Intro to Copper Pipeline

Copper pipelines have actually been a keystone of modern-day facilities for decades, renowned for their longevity, adaptability, and outstanding thermal conductivity. These pipelines are extensively used in pipes, heating, air conditioning, and refrigeration systems as a result of their capacity to hold up against high stress and stand up to deterioration. This short article delves into the make-up, producing processes, applications, market fads, and future potential customers of copper pipelines, highlighting their transformative impact on numerous sectors.

(Copper Pipe)

Structure and Production Process

Copper pipelines are made from pure copper or copper alloys, which supply superior mechanical residential properties and resistance to environmental aspects. The primary basic material is copper ore, which undergoes smelting and refining to generate high-purity copper ingots. These ingots are after that processed with extrusion or attracting techniques to form smooth pipes of various sizes and wall surface densities.

Extrusion includes forcing molten copper with a die to produce long, continuous tubes, while attracting minimizes the diameter of pre-formed tubes by drawing them via progressively smaller sized dies. Both approaches make certain harmony and stamina, making copper pipes appropriate for requiring applications. Post-processing steps such as annealing and finish further boost their efficiency attributes. The result is a robust pipeline efficient in enduring severe conditions and supplying trusted solution for years.

Applications Throughout Numerous Sectors

Plumbing Solutions: In domestic and industrial structures, copper pipes are the recommended choice for water supply lines due to their resistance to deterioration, microorganisms growth, and high-pressure abilities. They can deal with both hot and cold water successfully, making certain secure and reliable plumbing systems. Copper’s natural antimicrobial residential properties also make it perfect for safe and clean water distribution, lowering the threat of contamination.

Heating, Ventilation, and Air Conditioning (A/C): heating and cooling systems rely greatly on copper pipelines for their warmth transfer efficiency and toughness. Copper’s superb thermal conductivity permits reliable warm exchange in boilers, radiators, and air conditioning systems. Its flexibility and ease of installment make it a versatile product for elaborate piping networks, ensuring optimum system efficiency and energy efficiency.

Industrial Applications: Industries such as chemical handling, power generation, and production use copper pipes for their resistance to deterioration and ability to handle hostile fluids and gases. Copper pipes are frequently employed in warm exchangers, condensers, and distillation columns, where their thermal residential properties and longevity are vital. Additionally, their electrical conductivity makes them appropriate for basing and electrical conduit applications.

Medical Gadgets: In the clinical field, copper pipes play a crucial function in crafting precision instruments and equipment. Their biocompatibility and non-reactive nature ensure client safety and security, while their mechanical residential or commercial properties provide durable functionality. Copper pipes are made use of in diagnostic imaging devices, medical devices, and sanitation equipment, providing remarkable efficiency and integrity.

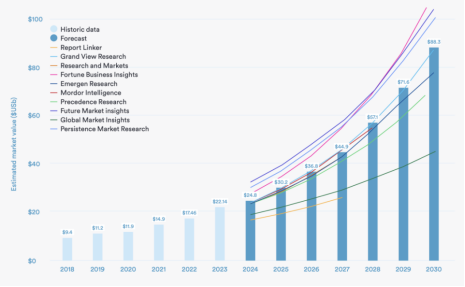

Market Trends and Development Chauffeurs: A Progressive Point of view

Sustainability Efforts: Environmental recognition has actually driven need for lasting products and techniques. Copper pipelines line up well with green efforts because of their recyclability and long life-span. Manufacturers are embracing environment-friendly manufacturing approaches and energy-efficient procedures to minimize environmental influence. Developments in waste reduction and resource optimization better boost the sustainability profile of copper pipes. As industries prioritize sustainability, the fostering of copper pipes will remain to grow, positioning them as leaders in eco-conscious options.

Technological Advancements: Quick developments in product science and producing technology have actually expanded the capacities of copper pipes. Advanced signing up with strategies, such as brazing and soldering, boost the stability and longevity of pipeline links. Smart piping systems that keep an eye on and change circulation prices and temperatures in real-time further boost efficiency and reliability. Suppliers embracing these technologies can offer higher-performance copper pipelines that meet stringent market requirements.

Healthcare Technology: Climbing healthcare expense and an aging population enhance the demand for advanced clinical devices. Copper pipelines’ biocompatibility and precision make them vital in developing cutting-edge clinical solutions. Individualized medicine and minimally intrusive therapies favor sturdy and trusted products like copper. Makers concentrating on healthcare technology can profit from the expanding market for medical-grade copper pipes, driving development and differentiation.

( Copper Pipe)

Difficulties and Limitations: Browsing the Path Forward

High Preliminary Prices: One obstacle related to copper pipes is their relatively high initial price contrasted to alternate products. The complicated mining and refining procedures contribute to this expense. However, the premium performance and expanded lifespan of copper pipes often warrant the financial investment over time. Producers need to consider the upfront costs against long-lasting advantages, considering aspects such as minimized maintenance and enhanced product high quality. Education and presentation of worth can help get over cost obstacles and promote broader fostering.

Market Variations: The cost of copper is subject to market changes, influenced by global supply and demand dynamics. Economic slumps and geopolitical stress can cause volatility in copper prices, influencing the price of copper pipes. Manufacturers require to implement strategies to reduce rate dangers, such as hedging and branching out supply chains. By staying informed and positive, they can browse market unpredictabilities and keep affordable rates.

Future Prospects: Technologies and Opportunities

The future of copper pipes looks encouraging, driven by raising demand for high-performance materials and progressed piping innovations. Ongoing r & d will result in the development of new qualities and applications for copper pipes. Advancements in nanotechnology, composite materials, and clever piping systems will certainly better improve their efficiency and broaden their utility. As industries focus on precision, efficiency, and sustainability, copper pipes are positioned to play an essential duty fit the future of manufacturing and innovation. The continuous advancement of copper pipelines promises exciting possibilities for technology and development.

Final thought: Welcoming the Precision Change with Copper Piping

Finally, copper pipelines represent a keystone of contemporary facilities, providing unmatched resilience, thermal conductivity, and adaptability for demanding applications. Their varied applications in pipes, COOLING AND HEATING, industrial equipment, and medical devices highlight their value. Recognizing the advantages and difficulties of copper pipes enables producers to make informed choices and maximize emerging chances. Welcoming copper pipelines indicates embracing a future where accuracy satisfies integrity and innovation in modern-day design.

Concerning CopperGroup

CopperGroup is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality copper and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, CopperGroup dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for copper pipe and fittings, please send an email to: nanotrun@yahoo.com

Tags: Copper Pipe, copper pipework, copper tubing

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us